The data and report content in this article are sourced from startus insights.

The progress of the chemical industry mainly focuses on digitization, decarbonization, and automation. Startups integrate different technologies together to achieve automation and sustainable development in chemical production. These trends in the chemical industry indicate the direction of industry innovation in the coming years. For example, the Internet of Things will further promote high connectivity between various devices to improve material quality, asset performance, and worker safety.

In addition, real-time analysis and artificial intelligence can also generate valuable information to optimize production processes. At the same time, large-scale digitization and network connectivity can also bring huge network threats. Therefore, the chemical industry pays attention to blockchain algorithms to ensure the security of data and supply chain. This report was first released in July 2022 and updated in September 2023. The data and report content are sourced from startus insights

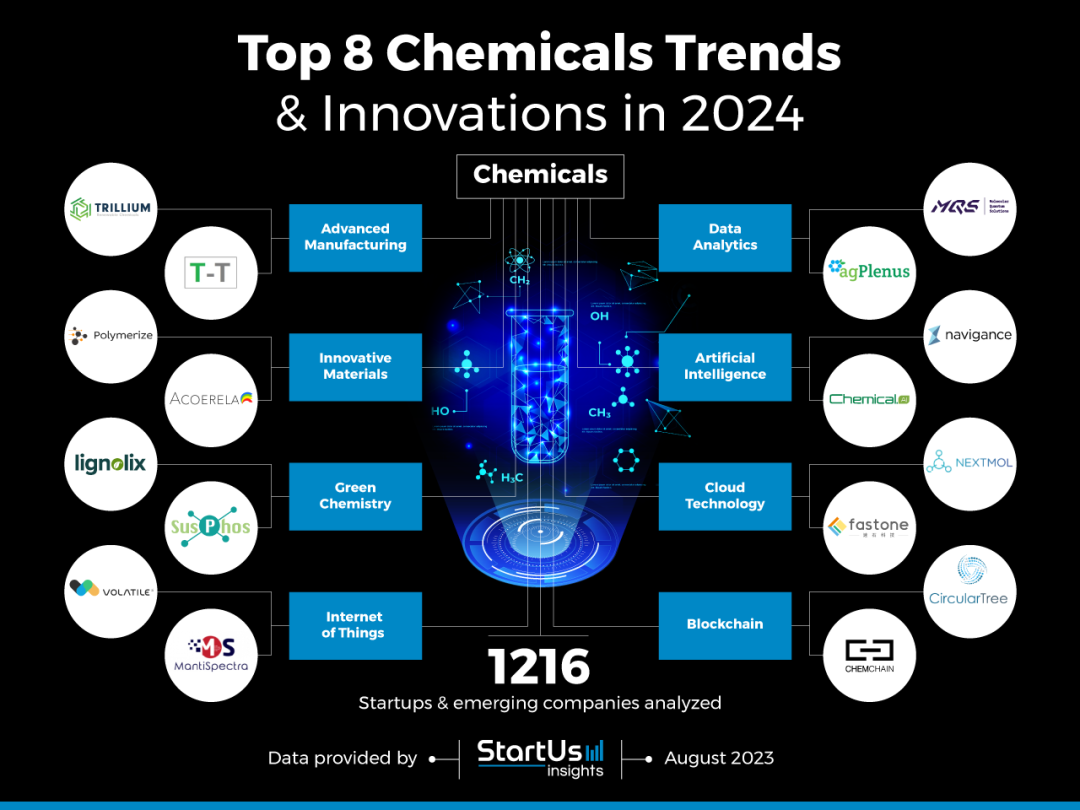

The innovation map outlines 8 major trends in the chemical industry and 16 promising startups.

In this in-depth study on top trends and startups in the chemical industry, a sample analysis was conducted on 1216 global startups and scale enterprises. This data-driven research provides innovative intelligence by outlining emerging technologies in the chemical industry, helping you improve strategic decisions. In the innovation map of the chemical industry below, you can have a comprehensive understanding of the innovation trends and startups that affect your company.

8 major trends in the chemical industry

● Advanced manufacturing

● Innovative materials

● Green Chemistry

● Internet of Things

● Data analysis

● Artificial intelligence

● Cloud computing

● Blockchain

Revealing the impact of eight major chemical trends

Based on the chemical innovation map, the following tree chart shows the impact of the eight major chemical trends in 2024. Innovations in the Internet of Things, artificial intelligence, cloud computing, and data analysis have driven the digitalization process of the chemical industry. The most common trend is advanced manufacturing, including technological advancements from immersive virtual reality technology to robotics to digital twins.

Innovative materials are another important trend, covering both biochemistry and nanotechnology. In addition, sustainable development and green initiatives have also become an important trend in encouraging the shift towards recycling and waste to energy solutions. Finally, network security requires blockchain based protection measures to bring traceability and transparency to the supply chain.

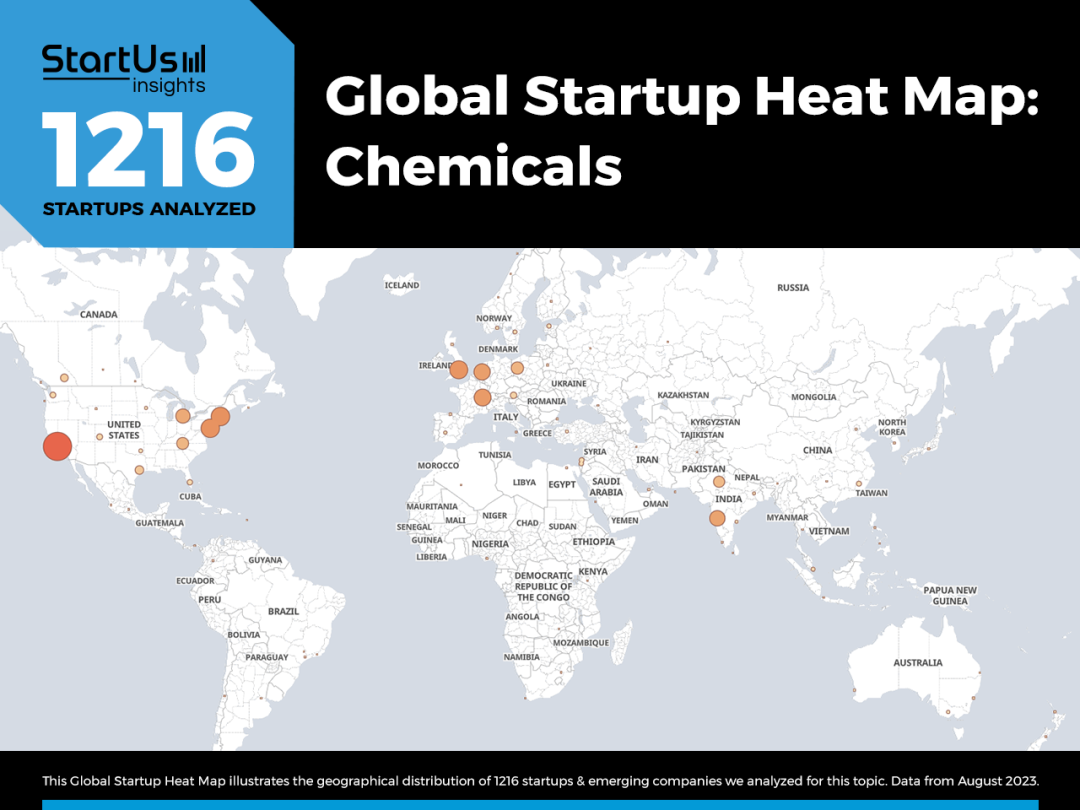

The global startup heat map covers 1216 chemical startups and large-scale enterprises

The "Global Startup Heat Map" below highlights the global distribution of 1216 model startups and scale enterprises studied and analyzed. According to the heat map drawn by the StartUs Insights platform, startups in Europe and North America have frequent activity, followed by India.

Below, we will introduce the typical 16 out of these 1216 startups and the solutions they have developed.

Eight major chemical innovation trends in 2024

1. Advanced Manufacturing

The progress in the field of chemical manufacturing increasingly involves digitization and automation. Extended reality technology can help chemical engineers solve labor shortages and employee training issues. It simulates crisis production scenarios together with digital twins and remotely diagnoses problems. 3D printing can also achieve automation in electrochemical device manufacturing, digital synthesis, and new material development.

In addition, robots can help factory technicians accelerate production in hazardous laboratory environments. AGV can transport goods without manual intervention. All of these advancements have made innovative new chemical manufacturing one of the main trends in the chemical industry.

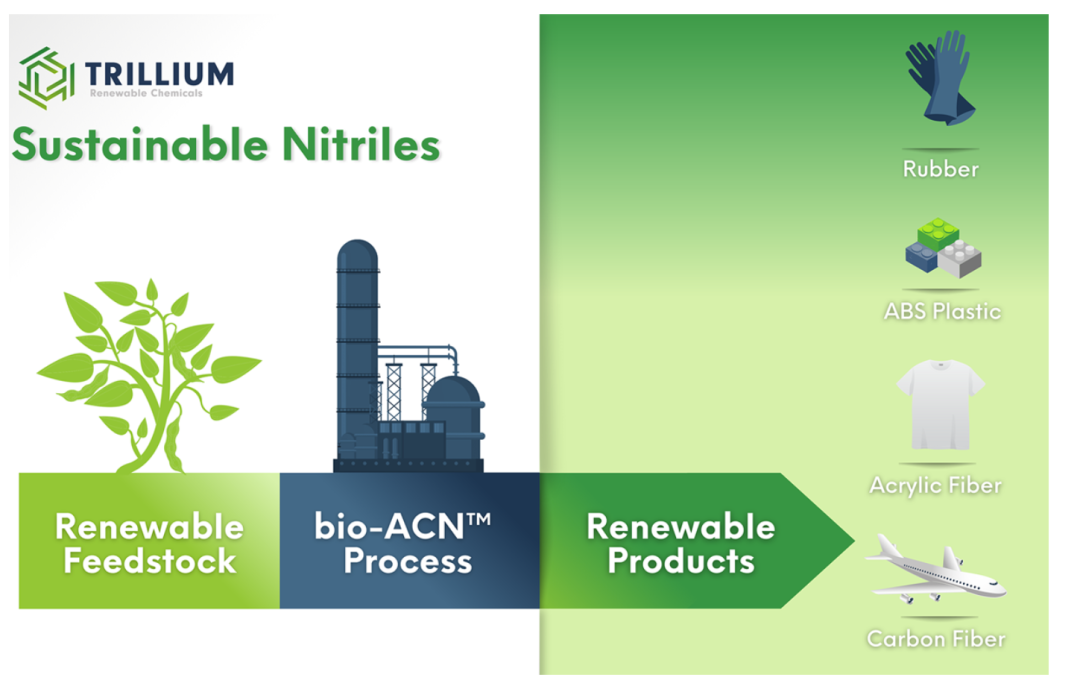

Trillium Renewable Chemicals Achieves Green Manufacturing

American startup Trillium Renewable Chemicals uses sustainable raw materials to produce plant-based acrylonitrile (www.trilliumchemicals. com). Traditional acrylonitrile is made from petroleum raw materials, which release a large amount of heat and produce toxic cyanide. This startup's patented technology replaces fossil fuels with bio renewable materials

Raw materials. It adopts thermochemical catalytic reactions and does not require biotechnology. This method avoids long-distance transportation of hazardous products, and also has cost-effectiveness, no health risks, and scalability.

Tree Tower Promotes Intelligent Chemical Manufacturing

Tree Power (www.tree tower. eu) is an Italian startup that develops innovative customized software for intelligent chemical manufacturing. The company's product portfolio includes computer-aided engineering, machine learning, and digital twin solutions. It also provides sensor networks and big data analysis. These technologies help chemical enterprises accelerate rapid prototyping design, virtual testing of materials and components, and product design optimization. In addition, Tree Power also provides tools for production manufacturing and advanced VR visualization.

2. Innovative materials

The trend of emerging innovative materials mainly focuses on advanced battery materials, nanomaterials, and biotechnology. Biotechnology solutions, such as overcoming the negative effects of petrochemical products through the production of bio based batteries, and this advanced cathode material improves the energy density and efficiency of batteries.

Another example is carbon fiber, which can extend the service life of wind turbine blades. In addition, nanotechnology has also helped discover new materials in fields such as polymers, such as a new material that can help improve the smoothness and heat resistance of coatings. The chemical industry can benefit from new materials by reducing carbon footprint and optimizing costs.

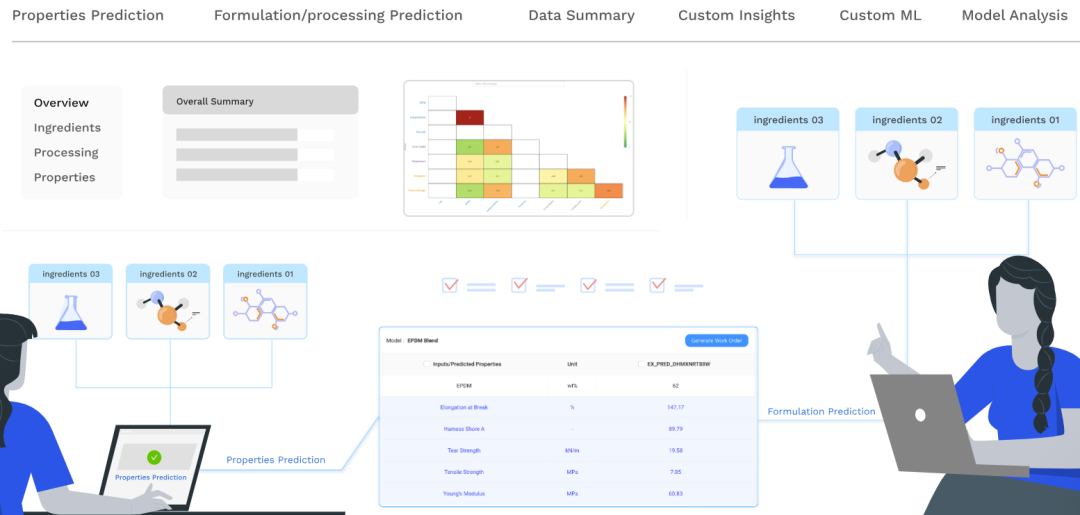

Polymerize

Polymerize (polymer. io/product/), a start-up based in Singapore, uses ML models to predict material properties before experiments. This platform provides predictions related to chemical formulations and data visualization. Therefore, it can help improve and optimize the decision-making of polymer enterprises, and accelerate research and development by adjusting experimental structures, methods, and schedules. In this way, Polymerize can enable products to enter the market faster.

Acoerela develops water-soluble lipophilic dyes

Acoerela (acoerela. com/products/), a start-up company headquartered in Singapore, has developed a water-soluble lipophilic dye platform that overcomes the limitations of poor solubility and aggregation of traditional dyes. Its dyes come in various colors and can be used to label extracellular vesicles, bacteria, and mammalian cells.

The company's Gram selective dyes can distinguish between Gram positive and Gram negative bacteria based on differences in cell wall structure. These membrane dyes can also track cells for multiple generations over a long period of time without producing toxicity. Acoerela is currently developing dyes that can emit light in the near-infrared II window for long-term non-invasive tumor imaging in living mice.

3. Green Chemistry

The focus of green chemistry is on processes and products that can eliminate the effects of hazardous or harmful chemicals and materials. This chemical trend has prompted manufacturers to prioritize environmental regulations and sustainable development. Chemical enterprises strengthen waste management by building recycling technologies and shift towards using alternative energy sources. For example, transitioning from petroleum raw materials to plant raw materials, converting biomass into fuel. Another example is green hydrogen gas, which converts carbon dioxide (CO2) emissions into hydrocarbons. In addition, green chemical solutions can also replace coke oven gas to achieve decarbonization in the steelmaking process.

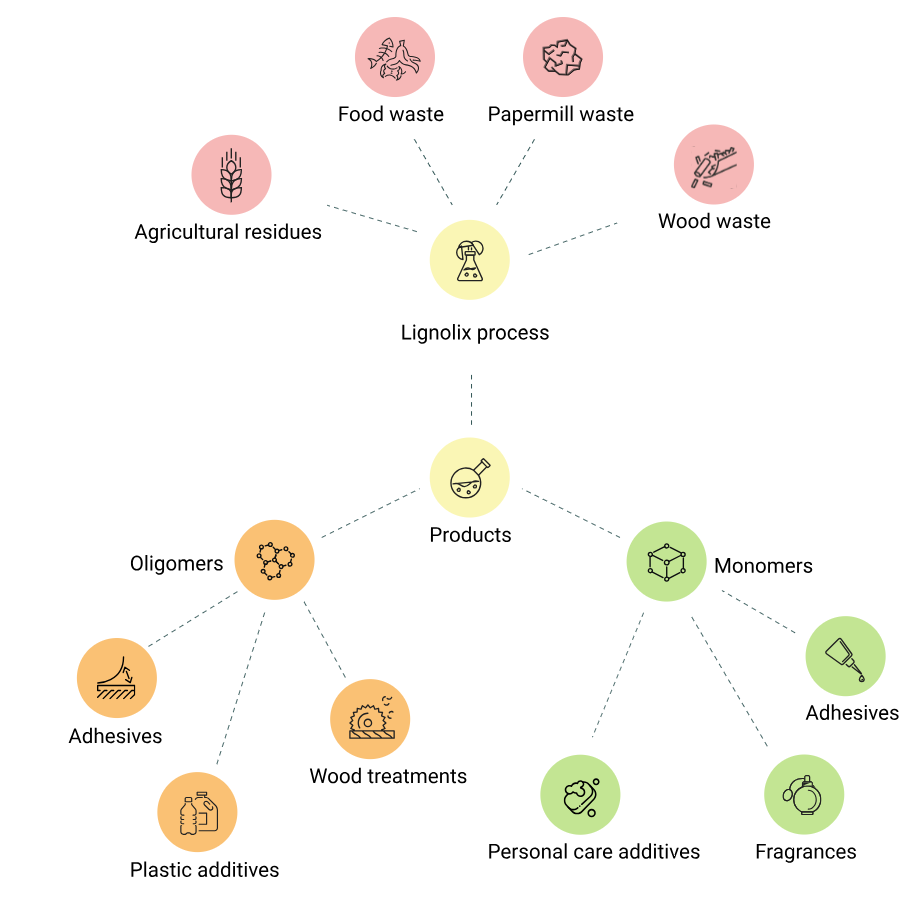

Lignolix develops lignin upgrading and recycling technology

Lignolix (www.lignolix. com/technology/) is a start-up company headquartered in the United States, committed to recycling lignin from plant waste into high-performance specialty chemicals. Due to the difficulty in handling the odor of lignin, this start-up company's technology can break it down into small pieces while retaining its functional characteristics. This method reduces the challenges of odor and color, and is also compatible with other products. The final product is suitable for cosmetics, adhesives, essence and spices, and the Lignolix technology is easy to expand.

SusPhos provides upgraded recycling technology for phosphate waste

SusPhos (www.susphos. com) is a start-up company from Denmark that uses intelligent chemical technology to upgrade phosphate rich waste. This startup produces waste free alternatives to products extracted from fossils. SusPhos' patented technology can provide high-quality flame retardants and sustainable phosphate products such as specialty fertilizers. (Domestic phosphorus chemical enterprises can download their patents and carefully study them)

4. Internet of Things

The chemical industry adopts the Internet of Things to collect and store operational data and simplify processes. The Internet of Things also helps to control material quality, asset performance, and worker safety. The obtained data can simulate and predict maintenance recommendations to extend the service life of assets. For example, operators can use sensor measurement data to avoid equipment overheating, thereby preventing unexpected shutdowns and production losses. Finally, the Internet of Things combines original equipment manufacturers (OEMs), operators, and service providers on one platform. This has brought unprecedented transparency to the supply chain of the chemical industry, making it the primary trend in the chemical industry.

Volatile uses electronic nose to analyze taste

British startup Volatile (volatile. ai) utilizes artificial intelligence and intelligent sensors to identify odors. This startup company integrates fragrance driver analysis, chemical composition filters, and electronic nose devices. Its electronic nose Scout2 is a metal oxide gas sensor that can detect odors and volatile organic gases. In addition, Scout2 adopts a modular design that is compatible with other major sensor manufacturers. This device can control air quality, monitor solid and liquid components, and is not affected by changes in environmental conditions.

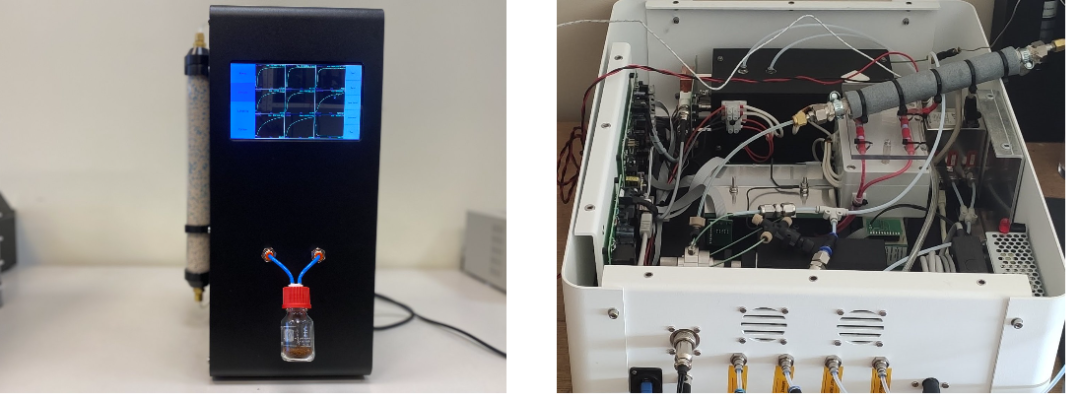

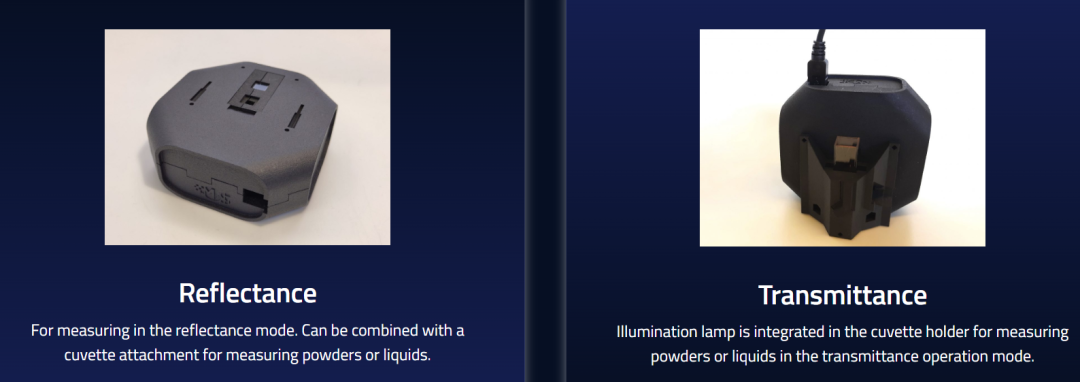

MantiSpectra Developed Portable (Chip Based) Spectral Sensors

Mantispecta (Mantispecta. com/our technology/) has developed a near-infrared (NIR) spectral sensor based on the indium phosphide platform. These sensors can identify and quantify the chemical information encoded by materials at wavelengths. It can also be calculated in a fast, non-contact, and non-invasive manner. Usually, traditional spectrometers are expensive and complex to use. However, Mantispectra's portable micro sensors can be easily installed in various devices, thus solving these challenges.

5. Data analysis

Advanced data analysis technology has improved the productivity and profitability of chemical production. The insight of big data can optimize energy consumption, factory operations, and supply chain. In addition, sensors and wireless devices can track the historical performance of manufacturing equipment. Based on these data, artificial intelligence algorithms can predict potential faults and their root causes, thereby reducing machine downtime.

Meanwhile, supply chain analysis can reduce the cost of each production step from raw material procurement to end-user delivery. In addition, manufacturers can easily analyze weather patterns and predict events that lead to supply chain delays. Like all industries today, the effectiveness of digital operations and analysis has had a significant impact on the chemical industry.

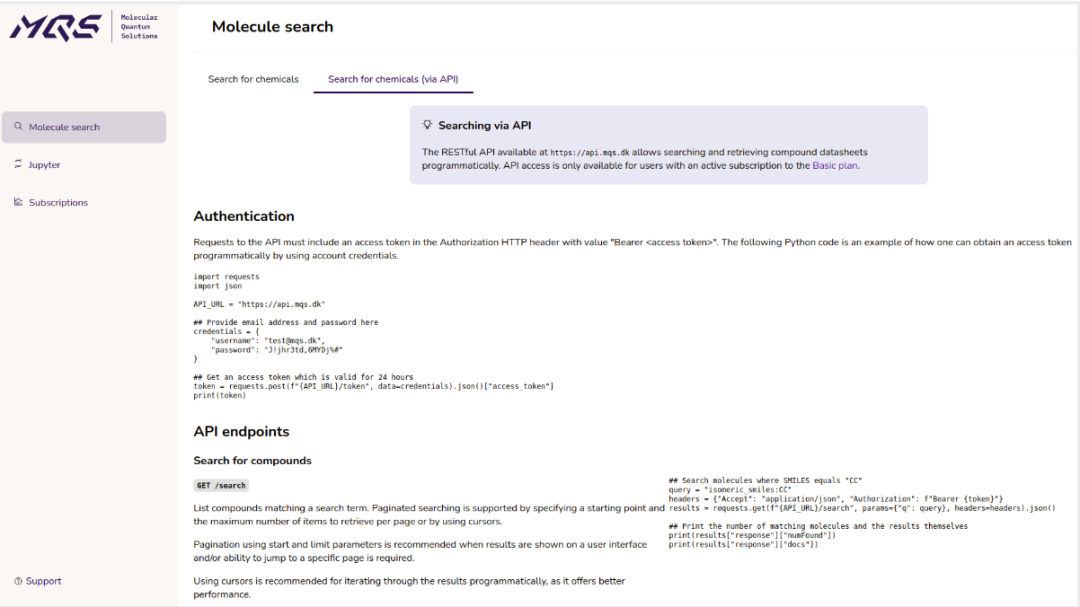

MQS is committed to quantum chemical integration

Danish startup MQS (mqs. dk) combines quantum based computing tools with thermodynamic modeling to calculate material properties. This startup has accelerated the research and development process in the pharmaceutical, biotechnology, and chemical industries. MQS software applies predictive models and algorithms to discover new materials for batteries and sustainable solvents, as well as new drugs and biodegradable plastics. This company deserves more careful study

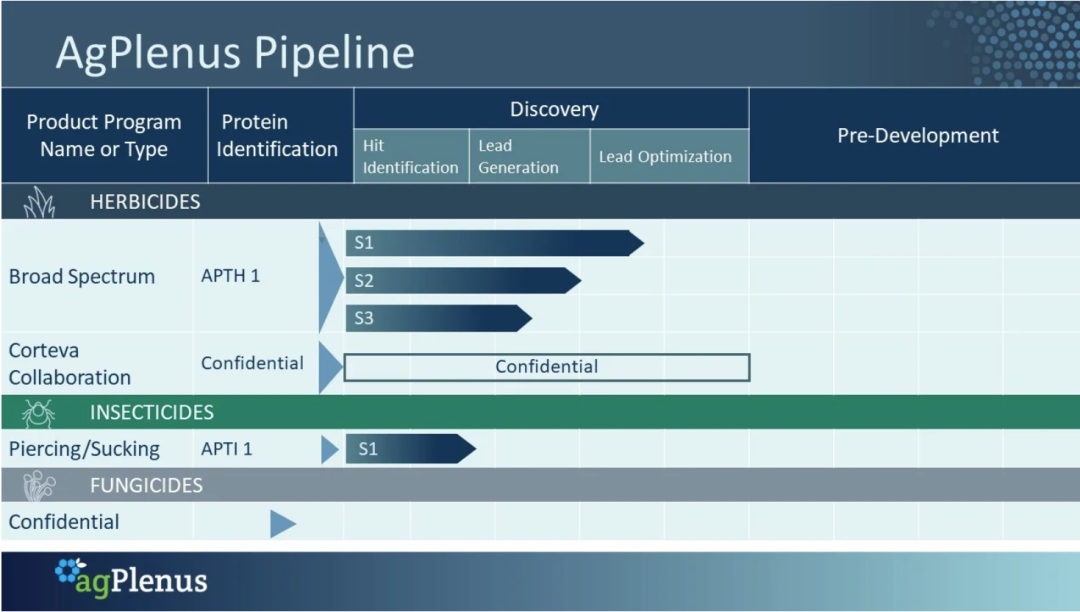

AgPlenus provides computational genomics services

Israeli startup agPlenus (www.agplenus. com/technology) provides predictive technology to discover new chemicals for crop protection. AgPlenus combines genomics, artificial intelligence, and big data to expand the chemical database and increase the probability of successful chemical product development.

6. Artificial Intelligence

In the chemical industry, laboratory experiments and clinical trials are strengthened through artificial intelligence and deep learning algorithms. This type of solution can lead to new biochemical formulas and material combinations. For example, new molecules with therapeutic properties or substitutes for dangerous or harmful substances. In addition, artificial intelligence can also automate chemical processes and collect valuable data to improve operational efficiency. Artificial intelligence solutions can also detect anomalies, leaks, or pollution in real-time and achieve early prevention. The widespread advantages and applications of artificial intelligence make it the most noteworthy trend in the chemical industry.

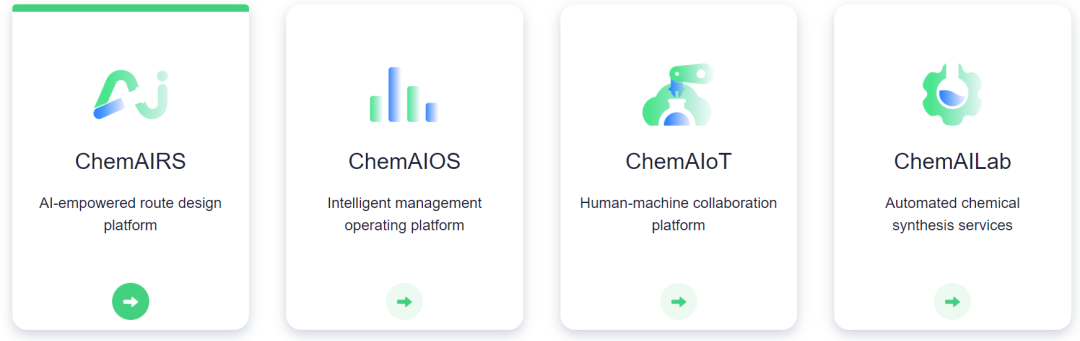

Chemical. AI provides synthetic planning based on artificial intelligence

Chinese startup Chemical. AI (chemical. ai) provides artificial intelligence and chemical informatics for synthesis planning. This startup's data-driven approach enables fast predictive inverse synthesis. It can generate multiple routes and discover new ones. Artificial intelligence assisted design considers synthesis steps, synthesis difficulty, route feasibility, and synthesis strategies. Therefore, human-machine evaluation tools have accelerated the development speed of innovative drug elements.

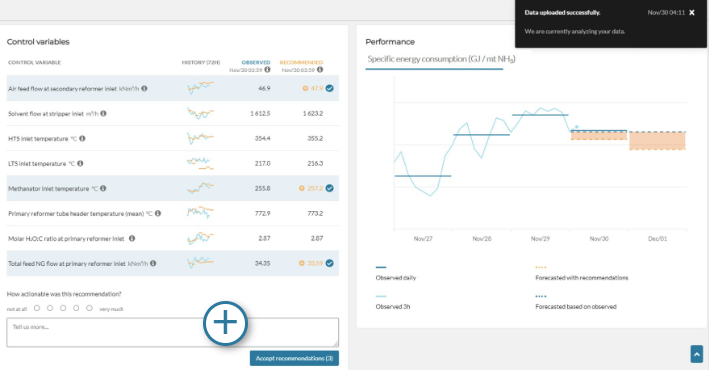

Navigation provides artificial intelligence for the manufacturing industry

Navigation (www.navigance. com/optimization engine) is a German start-up company that provides artificial intelligence driven SaaS platforms. This platform has achieved digitization and optimization of chemical production processes. Navigation collects data from chemical plants and utilizes artificial intelligence and advanced analytical techniques for rapid cloud computing to discover abnormal patterns. Based on this data, Navigation sends predictive alerts and automatic recommendations. This not only improves process efficiency and production, but also reduces energy consumption and development costs. (This is similar to Aspen Hysys, but it is a hybrid model that can be used for factory monitoring, performance monitoring, and optimization)

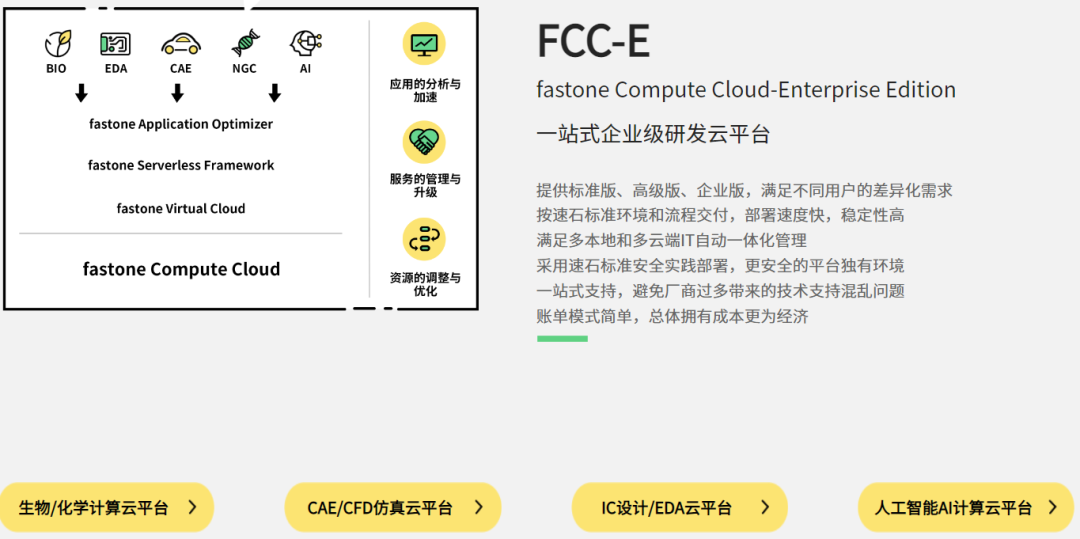

7. Cloud computing

Due to the increasingly time-consuming implementation of innovation, cloud computing is rapidly gaining attention. Cloud computing tools can perform extensive calculations to find material and chemical compatibility. In addition, cloud computing based solutions are easy to scale and do not require significant capital investment during deployment. Cloud data storage can flexibly, securely, and quickly store and exchange information. It can also reduce operational costs and supply chain risks. Another focus of cloud computing startups is network security, as the industry needs to handle highly sensitive data containing information such as chemical formulas.

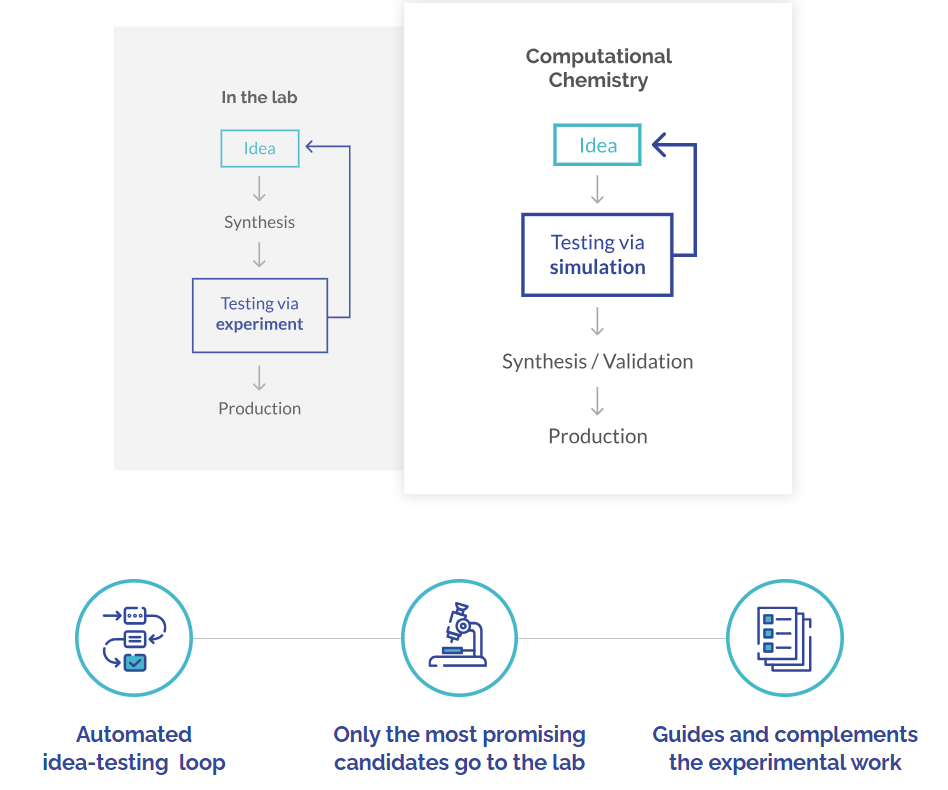

Nextmol establishes a cloud based chemical design laboratory

Nextmol (www.nextmol. com/product/) is a cloud based molecular modeling startup in Spain that utilizes artificial intelligence to design new chemicals. This startup combines atomic scale models with computational chemistry. It can describe molecular characteristics, simulate difficult to achieve experimental conditions, and predict the most promising molecules. In addition, Nextmol can also identify the reasons for laboratory failures. In order to achieve fast and reliable results, this startup also offers high-performance cloud computing.

Fastone provides a multi cloud computing platform

Fastone (fastonetech. com/product/bio) is a Chinese startup that develops cloud based solutions for automotive, life sciences, and intelligent manufacturing. Based on the serverless and Application Definition Cloud (ADC) framework, Fastone has built a cheap, fast, and scalable computing platform. It can be used for drug discovery and electronic design automation. This startup's online computer-aided engineering simulation platform can also perform high-performance computational modeling on any device. It can run finite element analysis (FEA), computational fluid dynamics (CFD), and thermal analysis. In addition, Fastone also provides a cloud platform for bioinformatics and exploratory data analysis.

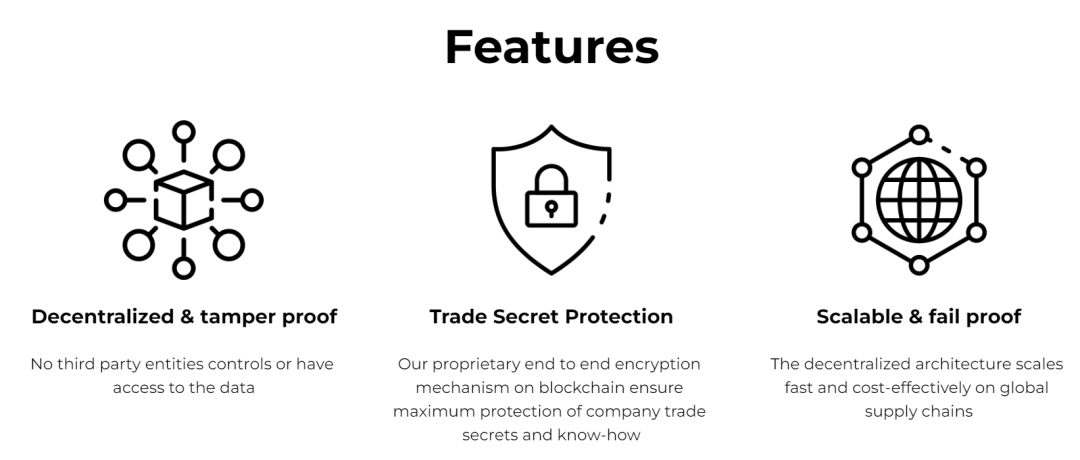

8. Blockchain

From raw materials to manufacturing, blockchain technology can track chemical products. In addition, blockchain technology can even monitor individual molecules at each step of the supply chain. Blockchain provides trusted data, understanding of customer needs, and an undeveloped revenue model. In addition, blockchain can also reveal consumption patterns and optimize demand planning. Therefore, it can eliminate excessive inventory, rush orders, and scheduling challenges. Smart contracts further provide distributed autonomous control to ensure quality and reduce errors during testing.

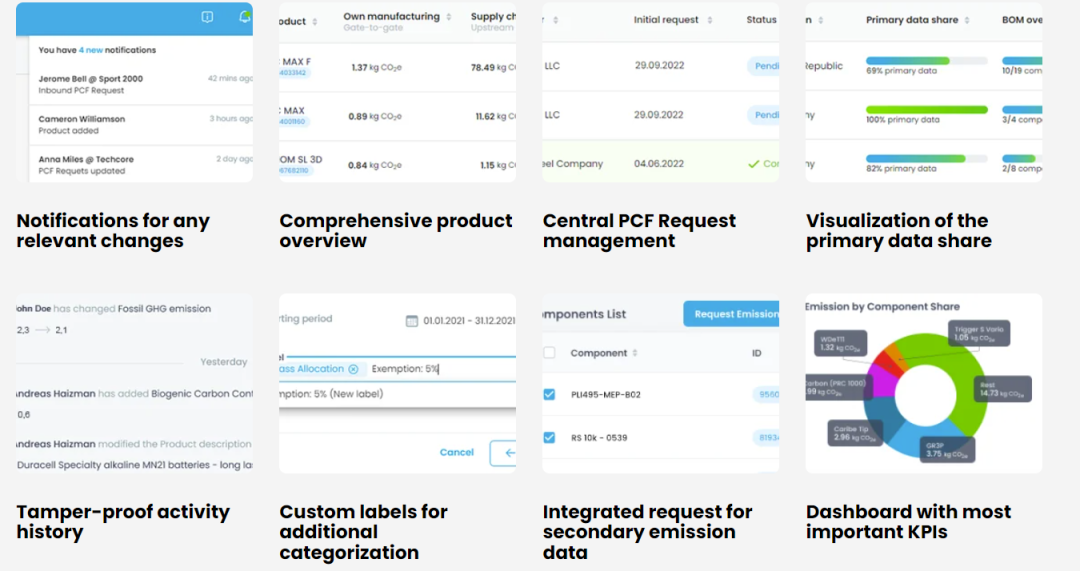

CircularTree provides a circular supply chain solution

CircularTree (www.circulartree. com) is a German start-up that creates a circular supply chain. This startup's blockchain ecosystem simplifies the sustainability (CSR) and compliance (ESG) responsibilities of the supply chain. The transparent automation of workflow further eliminates ambiguity among stakeholders. CircularTree makes the compliance management process trustworthy. In addition, its digital twin solution can also enable manufacturers to coordinate the logistics of chemical materials in real-time.

Chemchain achieves chemical tracking

Brazilian startup Chemchain (Chemcha. in/# features) has developed a SaaS blockchain platform. This platform tracks and transmits information along the chemical value chain. The startup adopts a decentralized approach that protects third-party data access through end-to-end encryption. Its algorithm also records historical information of raw materials, such as time delays, additional costs, and human errors for specific chemicals. Chemchain allows customers to control confidential data and selectively disclose it, overcoming the limitations of secure communication.

These chemical industry trends promote digital transformation and sustainable development while optimizing production processes and discovering new materials. These chemical solutions also build an interconnected intelligent value chain, improving the efficiency, profitability, and transparency of the entire industry.

Grasp trends and anticipate the future.